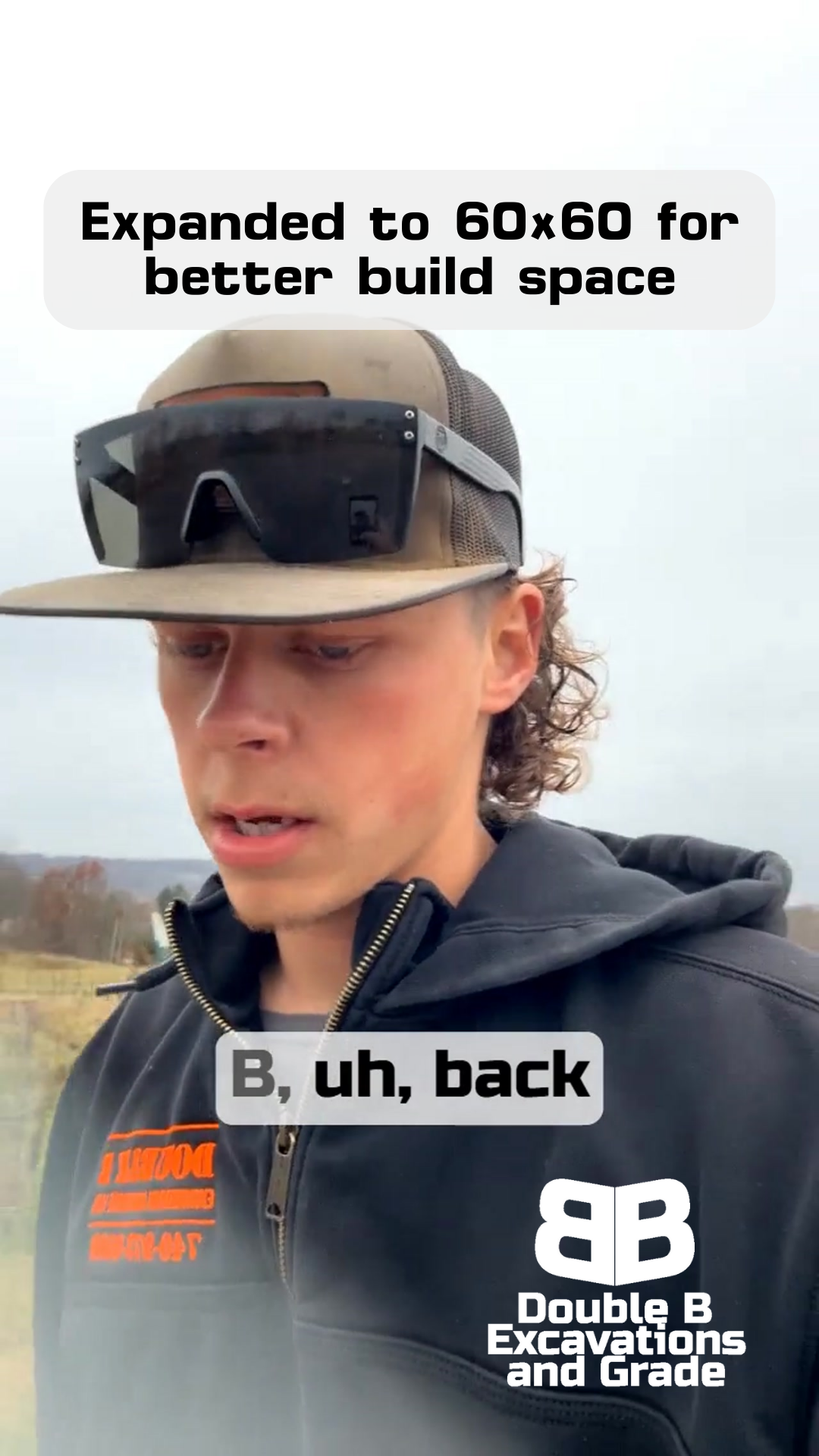

Skid Steer Troubleshooting: How We Keep Projects Moving Forward

Double B Excavations & Grade LLC

When Equipment Acts Up, The Job Still Needs to Get Done

REAL SOLUTIONS FROM A REAL JOB SITE

It's 5:30 in the evening, and we're still out here working.

Not because we want to be pulling extra hours, but because sometimes that's what it takes to get the job done right.

When you're dealing with equipment issues, you've got two choices: pack it up and head home, or figure it out and keep moving. At Double B, we always choose the latter.

Today's story isn't about perfect equipment or flawless execution - it's about what happens when things go wrong and how we handle it.

Because let's be honest: if you work with heavy equipment long enough, something's eventually going to act up. It's not about if, but when.

Welcome to Double B!

The Situation

We're out here trenching and laying conduit - pretty straightforward work when everything's running smooth. But our skid steer had other plans. Last week, we ran into some issues that we thought we had fixed. Found a broken wire that had rubbed through between the frame rails and the boom lift. Pretty common problem actually - the constant movement can wear through even the toughest wire protection.

Fixed that issue, and everything worked great for about four or five days. The machine was running like a champ, doing exactly what we needed it to do. Then today rolls around, and wouldn't you know it - same symptoms, different day. This time it's throwing codes after we shut the battery switch off overnight. Not exactly what you want to deal with when you've got conduit waiting to go in the ground and a project timeline to meet.

Troubleshooting Process

Here's something they don't teach you in equipment school - machines have personalities, and sometimes they like to keep you guessing. After our first round with the wire issue, we thought we had it nailed. The repair was solid, everything checked out, and the skid steer was performing exactly like it should. But machinery isn't always that simple.

When the codes started showing up again after shutting off the battery switch, we knew we had to dig deeper. It's not just about fixing what's broken - it's about understanding why it broke in the first place. That space between the frame rails and boom lift? It's a notorious spot for wear and tear. Every lift, every drop, every movement can cause friction we can't see until something stops working.

Real-World Solutions

Here's where experience really comes into play. Sure, we could've called it a day when the problems started up again. Plenty of contractors would have. But we've learned over the years that stopping mid-job often causes more problems than it solves. Instead, we took a practical approach: fix what we can, keep a close eye on the repairs, and focus on getting the immediate work done.

Sometimes that means working a bit later than planned. Sometimes it means double-checking your work between tasks. But it always means keeping the project moving forward while making sure everything's safe and solid. Because at the end of the day, that trench needs to be dug, and that conduit needs to go in.

Lessons Learned

The biggest lesson here isn't about wires or codes or battery switches - it's about mindset. Equipment problems aren't failures; they're opportunities to learn something new about your machinery. Every time we troubleshoot an issue like this, we add another piece to our knowledge base.

We've learned to look for wear points before they become problems. We've learned that sometimes the simplest solution isn't always the complete solution. But most importantly, we've learned that keeping a level head and staying focused on the end goal is what gets projects done, even when things don't go as planned.

Moving Forward

When it comes to equipment issues, prevention is worth a pound of cure - but you can't prevent everything. That's why we've developed a system for handling these situations. First, we always keep basic repair supplies on our trucks. Those extra few minutes gathering supplies can save hours of downtime later. Second, we stay up to date on our maintenance schedules. And third, we know when to call in the experts - sometimes that's the smartest move you can make.

For this particular skid steer, we're keeping a close eye on that wire area. We might need to add some extra protection or reroute some components, but for now, we're documenting everything we find. That's another key point - keeping track of what works and what doesn't helps prevent the same problems from surprising us in the future.

Closing

Today's project wrapped up successfully - got the trench dug, conduit laid, and everything backfilled. Sure, it took a little longer than planned, but that's just part of the job sometimes. The important thing is we kept moving forward, solved the immediate problems, and got the work done right.

Looking Forward

If you're dealing with equipment issues on your job site, remember this: every contractor faces these challenges. It's not about having perfect equipment - it's about how you handle the imperfect moments. Sometimes the difference between a good day and a bad day is just your approach to solving problems.

Need help with site work in central Ohio? Whether your equipment's running perfect or giving you fits, we've got the experience to get your job done right. Because at Double B, we don't just work through problems - we learn from them.