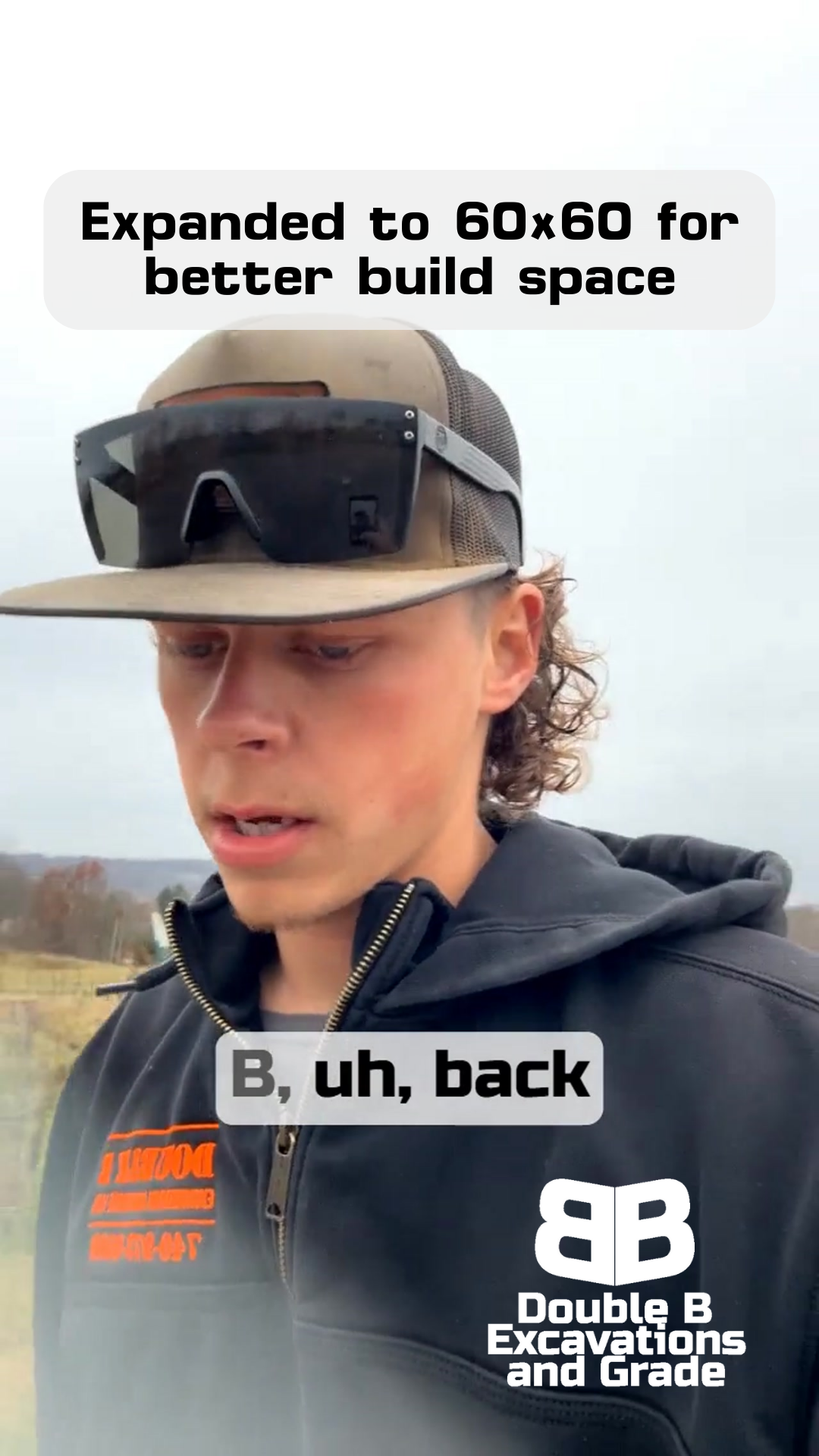

Driveway Done Right: How Proper Stone Layering Made This Westerville Project Shine

Double B Excavations & Grade LLC

Built to Last. Made to Impress.

A FINISHED PRODUCT THAT SPEAKS FOR ITSELF

When a customer's eyes light up at their new driveway, that's when you know you've done something special.

That's exactly what happened today in Westerville, where we just wrapped up a complete driveway transformation that even surprised me - and I've been doing this work for years.

You might think a driveway is just a place to park your car.

But when it's done right, with proper materials and careful attention to detail, it becomes something more.

It's not just about looking good (though this one certainly does).

It's about building something that's going to last, something that the homeowner can be proud of every time they pull in.

Welcome to Double B!

Project Overview

Let me break down exactly what went into this Westerville project. We're talking about 140 tons of stone total - that's not a typo. Specifically, we used 80 tons of 304 stone and topped it with 60 tons of 57s. When I told the customer how much stone we'd be bringing in, I could tell they were surprised. Truth is, I was a bit taken aback myself when I ran the numbers.

But here's the thing about doing it right: sometimes it takes more material than you might expect. Our focus wasn't just on making it look good today. We wanted to build something that would hold up for years to come. That meant starting with proper surface preparation using our Harley rake to get everything just right, then carefully layering and compacting each type of stone.

The whole project came together exactly as planned, with careful attention to every detail along the way. From the initial prep work to the final roll, every step mattered. And seeing the customer's reaction to the finished project? That's what makes this work worthwhile.

The Step-by-Step Process

Let me walk you through exactly how we tackled this project. Everything starts with proper surface preparation - that's why we brought in the Harley rake. Think of it like preparing a canvas before painting. This tool helps us get everything smooth and level before we even think about laying stone.

Once we had our surface prepped, we started with the 80 tons of 304 stone. But here's where attention to detail really matters: we didn't just dump it and spread it around. After each load, we took the time to roll it three or four times. Some might call this overkill, but this extra effort is what makes the difference between a driveway that lasts and one that needs constant repairs. We kept working the edges too - not because we had to, but because these small details add up to a better final product.

Why These Methods Matter

You might be wondering why we put so much effort into something as seemingly simple as a driveway. Here's the truth: I've seen plenty of driveways fail because someone tried to cut corners. Maybe they skipped the proper preparation, or they tried to save money by using less stone. But in this business, those shortcuts always come back to haunt you.

That's why we take the time to do things like rolling between each load of stone. When that second layer of 57s went down - all 60 tons of it - we treated it with the same care as the base layer. First truck comes in, we spread it, roll it. Second truck, same thing. Every pass with the roller locks those stones together a little tighter, creating a surface that's not just stable today but will stay that way for years to come.

Rolling between loads might take more time, and bringing in 140 tons of stone might seem like a lot, but when you see the finished product - and more importantly, when you see how it holds up over time - you understand why we do things this way. In Westerville, our customers don't just need a driveway that looks good in photos. They need something that's going to stand up to Ohio weather and daily use.

Behind the Quality

There's something satisfying about watching a project come together exactly as planned. Every pass with the roller, every careful check of the edges, it all adds up. But what most people don't see is the thinking that goes into the timing and sequence of everything.

Take today's project - we made sure to get all the 304s down and properly compacted before bringing in the 57s. That might seem obvious, but you'd be surprised how many try to rush the process. We've learned over the years that patience isn't just a virtue - it's a requirement for quality work. When you're dealing with 140 tons of stone, there's no room for shortcuts.

Closing

Standing there in Westerville today, catching my breath and looking at the finished driveway, I couldn't help but feel grateful. We're blessed to be able to do this kind of work every day, transforming properties and exceeding expectations. When the customer walked out and their eyes lit up, that made all the extra effort worth it.

Looking Forward

If you're thinking about a driveway project, remember this: the right way might not be the quickest or cheapest way, but it's always the best investment in the long run.

Whether you're in Westerville or anywhere else in central Ohio, we're happy to take a look at your property and discuss what it would take to do the job right.

Because at the end of the day, that's what it's all about - not just getting the job done, but getting it done right.

When we drive past this property months or years from now, we know this driveway will still be performing exactly as it should.

That's the Double B difference, and that's why we take such pride in our work.