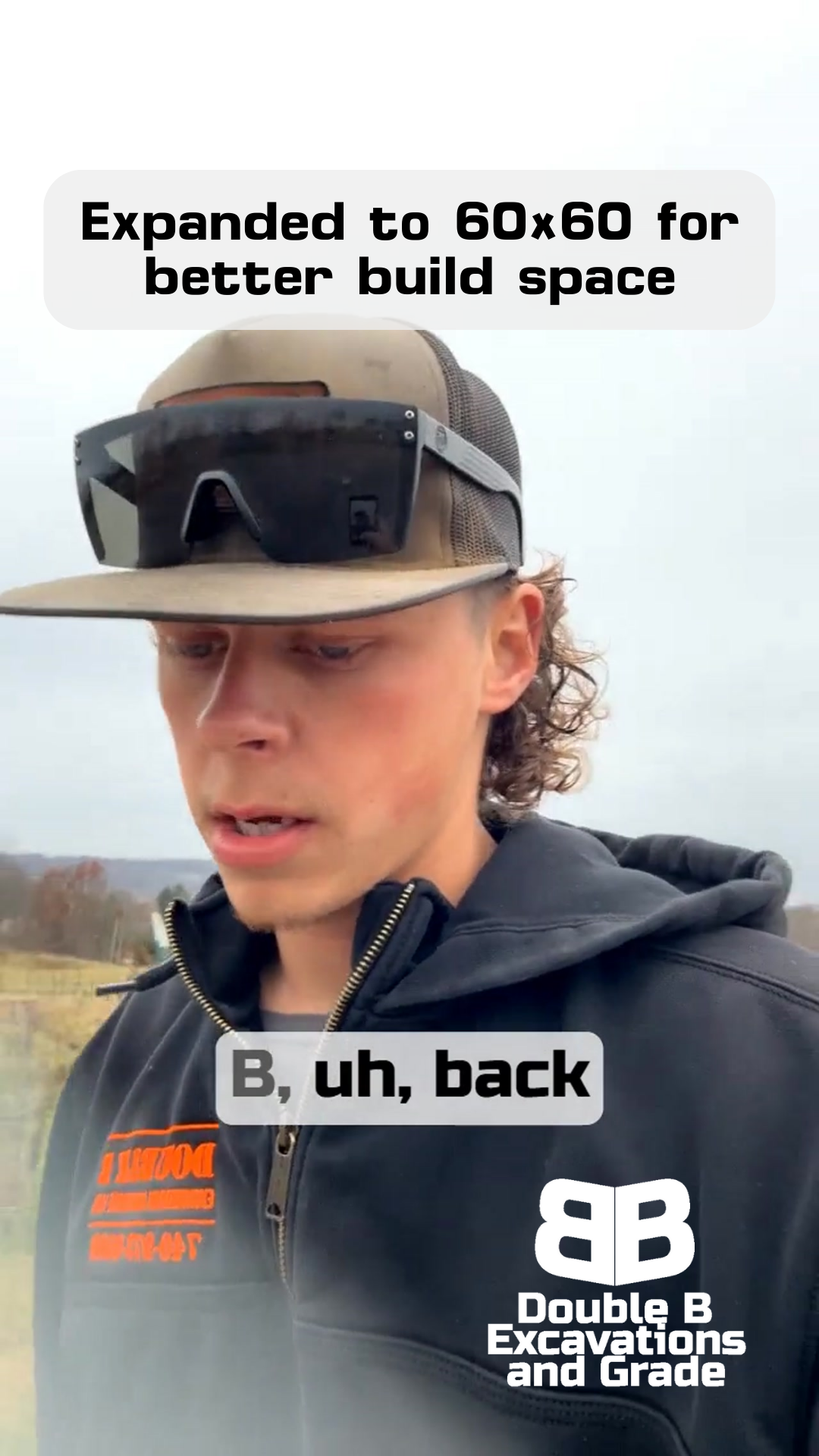

Culvert Installation Basics: Creating a Safe Creek Crossing That Lasts

Double B Excavations & Grade LLC

Built to Last, Even in the Mud

SOLVING STORMFLOW AND ACCESS ISSUES FOR GOOD

There's nothing quite like wrapping up a tough job at 8 PM, knowing you've built something that'll serve its purpose for years to come.

Today, that's exactly where Easton and I found ourselves - muddy but satisfied after installing a 48-inch culvert for a creek crossing.

It might not be the most glamorous part of construction, but get this wrong, and you'll have bigger problems than mud on your boots.

When it comes to creek crossings, there's no room for shortcuts.

Whether you're building a driveway or creating access to a property, that crossing needs to handle everything nature throws at it - from normal creek flow to heavy storms, and from everyday traffic to heavy equipment.

One washout can mean lost time, expensive repairs, and a lot of headaches for property owners.

Welcome to Double B!

Project Overview

Let me walk you through what we tackled today. We're talking about installing a 48-inch culvert - that's a pipe four feet across - to create a safe, stable creek crossing. The conditions weren't exactly ideal - plenty of mud to go around - and we had to work around an existing AT&T line. But here's the thing about excavation work: you deal with what the site gives you.

Our customer needed two things from us: they needed to be able to cross the creek safely by the end of the day, and they needed this crossing to last. That means doing more than just dropping a pipe in the ground. We brought in specific materials - #2 stone, rip rap, and 304s - each serving a particular purpose in creating a stable crossing. We also had to coordinate with future work, including an asphalt contractor who'll put the finishing touches on the surface.

The Installation Process

When you're putting in a culvert this size, every step matters. That 48-inch pipe we chose wasn't just a random pick - it's what this creek needs to handle water flow without backing up or washing out. Think about it like this: too small, and you're asking for flooding problems; too big, and you're spending money you don't need to.

The stone selection is just as important as the pipe size. We start with #2 stone - these are the bigger pieces that lock together to create a solid foundation. Then comes the rip rap, which helps protect against erosion where the water enters and exits the culvert. You might hear some contractors skip this step to save money, but we've seen what happens when you do that. One good storm, and you're looking at repairs that cost way more than doing it right the first time.

Why These Components Matter

Let's break down why each part of this system matters. That 48-inch pipe gives plenty of room for water flow, even during heavy rains. But it's not just about the pipe - it's about everything around it. The #2 stone foundation keeps everything stable, while the rip rap works like armor where the water hits hardest. We top it all with 304s to create a smooth driving surface that ties into the future asphalt.

Working around that AT&T line wasn't just about being careful - it was about understanding how everything fits together. We knew it was there, got clearance to work with it, and made sure our installation wouldn't cause problems down the road. That's the kind of detail work that separates a lasting installation from one that'll need fixes in a few months.

This might seem like overkill to some folks, but here's the truth: in excavation work, you're not just building for today. You're building for every storm, every heavy load, and every season change that's coming. When you understand that, taking the time to do each step right just makes sense.

Project Management Realities

Let me give you a real look at how these projects come together. By the time we wrapped up at 8 PM, we had a working creek crossing - but that doesn't mean we're completely done. We left some dirt piled up and have cleanup work to handle in the morning. Being upfront about this with the customer is just part of doing business right.

There's a rhythm to these jobs that comes from experience. You've got to coordinate with other contractors - in this case, the asphalt team that'll finish the surface. We cut the existing asphalt clean and flush, giving them a good edge to work with. It's about thinking ahead and making sure everyone who comes after us can do their job right too.

Wrapping It Up Right

At the end of the day, what matters most is that we met our main goal: the customer can safely cross their creek tonight. Tomorrow, we'll be back to clean up and handle the finishing touches. That's just how we do things - complete the critical work first, then make sure everything's cleaned up and looking right.

Looking Forward

If you're considering a culvert installation or creek crossing project, here's what I want you to remember:

- Size matters - make sure your culvert can handle your water flow

- Don't skip the protective materials like rip rap

- Think about future maintenance and access

- Work with contractors who understand the whole picture, not just their piece of it

Every creek crossing is different, but the principles stay the same: build it right, build it to last, and make sure it serves its purpose day in and day out. Because at the end of the day, that's what we're here for - creating solutions that work for the long haul.

Want to talk about your creek crossing needs? We're always happy to take a look and help you understand your options. After all, the best time to plan for these projects is before you need them.