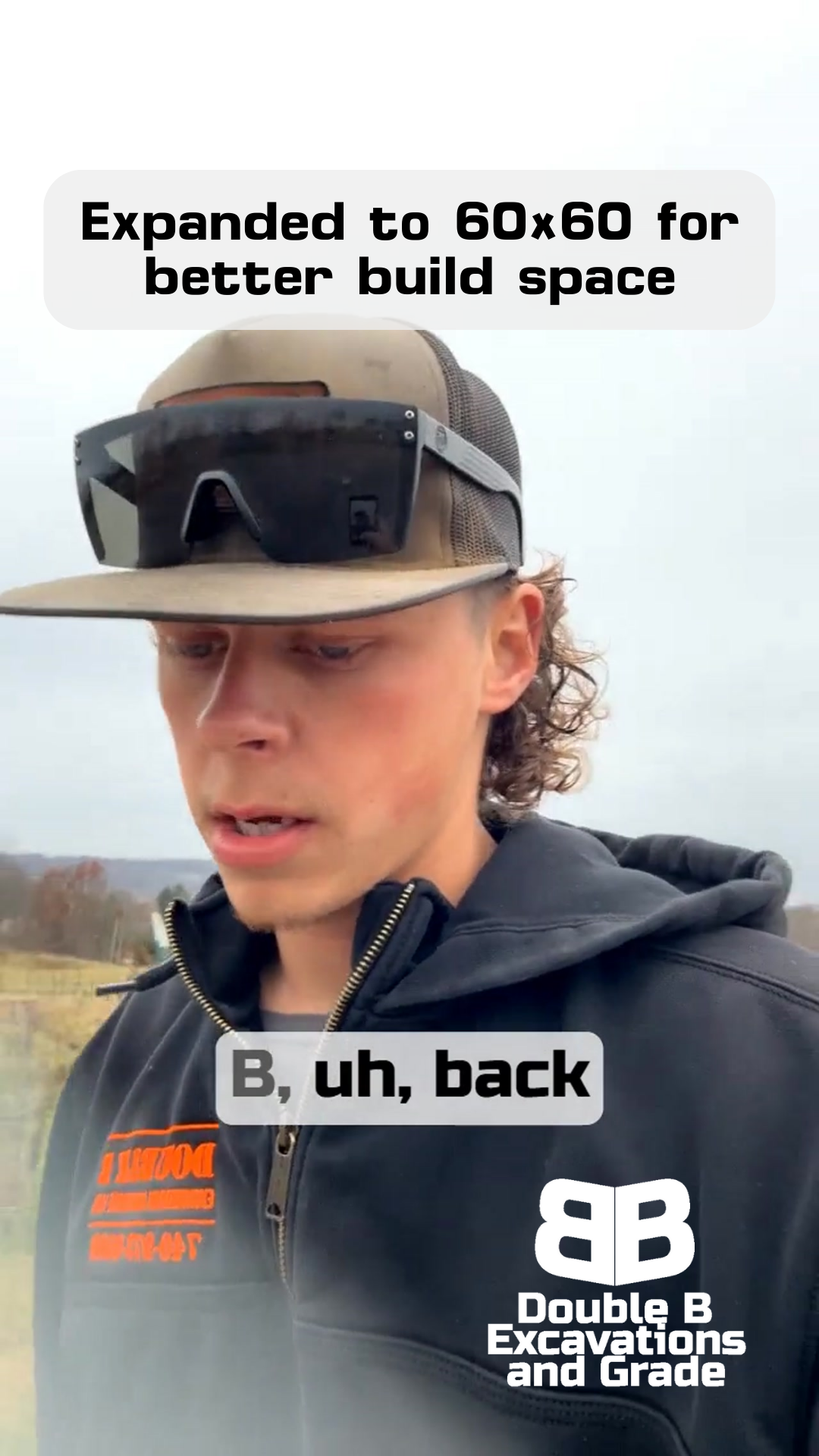

Building a Construction Driveway Around Septic Lines: A 280-Foot Project Guide

Double B Excavations & Grade LLC

Working Around What Matters

WHY CAREFUL PLANNING MAKES OR BREAKS YOUR CONSTRUCTION ACCESS

When you're building a construction driveway, what you can't see is just as important as what you can.

Today we're about an hour and a half from our shop, tackling a 280-foot driveway installation that's teaching a valuable lesson about working smart around existing infrastructure.

Those purple flags dotting the property might not look like much, but they're marking something crucial - septic lines that need protecting during the whole construction process.

This isn't just about laying down stone; it's about creating access while preserving what's already there.

Welcome to Double B!

Project Overview

Let's break down what we're dealing with here. We've got a 280-foot stretch that needs to become a 12-foot-wide construction driveway. That might sound straightforward, but here's what makes this job interesting: we're working around an existing septic system, dealing with leftover clearing debris, and planning for future asphalt requirements.

The numbers tell the story of how serious this project is. We're bringing in 180 tons of stone total - that breaks down to 110 tons of #2s and 70 tons of 304s. When you're working this far from home base, you need to get your calculations right the first time. There's no quick trips back to the shop for more materials out here.

This neighborhood has specific requirements too - all driveways eventually need to be asphalt. That means while we're building a construction driveway now, we're also thinking ahead about how our work today sets up the final product down the road.

Site Protection Measures

Those purple flags aren't just for show - they're our guide to keeping everything safe while we work. When you're dealing with septic systems, there's zero room for error. That's why we've got the whole area silt fenced in before we even think about bringing in heavy equipment.

Think of it like this: what's underground is just as important as what we're building on top. One wrong move with an excavator could turn a straightforward driveway job into a major headache for everyone. The silt fencing does double duty - it marks our work zone clearly and protects those critical septic lines from any disturbance.

The Construction Process

Before we can even think about laying stone, we've got some cleanup to do. The site was cleared before we got here, but clearing isn't the same as prepping. We're dealing with leftover debris that needs to be cleaned up before we can get down to actual dirt. It's like trying to paint a wall without cleaning it first - you've got to handle the prep work if you want the final product to last.

Once we get down to actual dirt, we're digging eight inches deep. That might sound like overkill, but there's science behind it. This depth gives us room for both layers of stone - our #2s for the foundation and 304s for the top layer. When you're building something that needs to handle heavy construction traffic, you can't cut corners on depth.

Technical Considerations

Working this far from our shop means every detail needs to be planned out. That stone delivery timing is crucial - we need those 110 tons of #2s first thing in the morning, with the 70 tons of 304s ready to follow. Being an hour and a half from home base means we can't afford any scheduling hiccups.

The 12-foot width isn't random either. It's what we need for construction vehicles to navigate safely, especially considering the driveway's length and how it curves around the property. Remember, this isn't just about getting a car in and out - we're building something that needs to handle concrete trucks, material deliveries, and all kinds of heavy equipment.

That's also why we pay so much attention to the stone selection. The #2s create a solid foundation that locks together under weight, while the 304s on top provide a smooth, stable surface. It's a combination we've proven works, especially when you're dealing with the kind of traffic a construction site sees.

Future Planning

While we're focused on building a solid construction driveway today, we're always thinking ahead. We know this driveway will eventually need to be asphalt - that's just part of the neighborhood requirements. So everything we're doing now needs to set up that future work for success.

There's potential for us to come back and handle more work here too. Final grading, drainage work - these are all pieces of the bigger picture. That's why we're extra careful about how we handle the site prep now. Good drainage planning during the construction phase makes everything easier when it's time for final grading.

Building a 280-foot construction driveway might sound straightforward, but as you can see, there's a lot more to it than just laying down some stone. When you're working around septic systems, dealing with site debris, and planning for future development, every step matters.

Looking Forward

If you're planning a construction project, especially one with existing infrastructure to protect, take the time to plan it right. Those purple flags on our site might seem like a hassle, but they're actually saving everyone time, money, and headaches down the road.

Need help figuring out the best approach for your construction site access? Whether you're dealing with septic systems, drainage concerns, or other site challenges, we're always happy to take a look. Because at Double B, we believe in doing it right the first time - even if that means driving an hour and a half to make it happen.